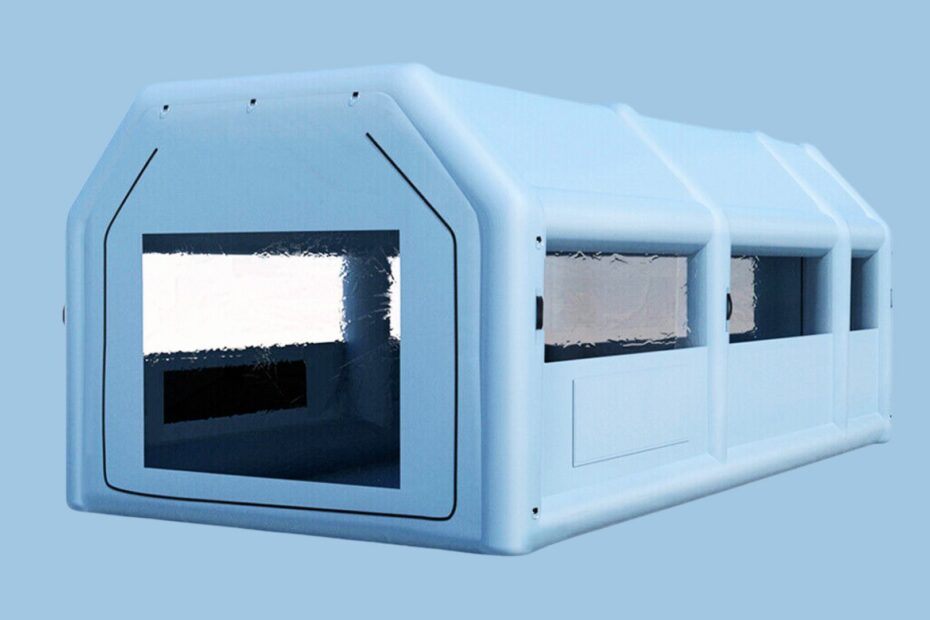

Inflatable paint booths are increasingly popular in various industries, primarily due to their flexibility and efficiency. A significant aspect of their appeal is how they manage overspray and contamination, crucial for maintaining quality and environmental compliance in painting projects.

Managing Overspray in Inflatable Paint Booths

- Ventilation Systems: One of the primary ways inflatable paint booths manage overspray is through efficient ventilation systems. These systems are designed to capture overspray and prevent it from escaping into the surrounding environment. Typically, the airflow within the booth is directed in such a way that overspray is drawn away from the painted object and captured by filters.

- High-Efficiency Filters: Inflatable booths often use high-quality, high-efficiency particulate air (HEPA) filters or similar filtration systems. These filters are capable of trapping very fine particles, ensuring that the air leaving the booth is free from harmful contaminants.

- Design and Layout: The design of the booth itself contributes to managing overspray. Many booths are designed with an airflow pattern that pushes overspray towards the filtration system. The interior surfaces are also typically smooth and non-absorbent, which helps in preventing the accumulation of paint particles.

Controlling Contamination

- Enclosed Environment: The very nature of an inflatable booth provides a controlled environment. Being fully enclosed, these booths significantly reduce the risk of dust, dirt, and other environmental contaminants affecting the painting process.

- Air Quality Control: Alongside ventilation, maintaining clean air within the booth is essential. This is achieved through a combination of air filters and positive pressure systems. Positive pressure helps in keeping out contaminants by ensuring that air flows out of the booth rather than in.

- Regular Maintenance and Cleaning: To maintain efficiency in controlling overspray and contamination, regular maintenance and cleaning of the booth are essential. This includes checking and replacing filters as needed and ensuring that the booth material itself is kept clean and intact.

Environmental Compliance

Inflatable paint booths also contribute to environmental compliance. By effectively managing overspray and containing harmful solvents and particles, they help in reducing air pollution. This is particularly important in industries where environmental regulations regarding volatile organic compounds (VOCs) and other pollutants are strict.

Advantages Over Traditional Booths

Compared to traditional paint booths, inflatable booths offer several advantages in managing overspray and contamination. Their portability allows for setup in locations with optimal environmental conditions, and their design can be quickly adapted to different project needs. Additionally, the ease of setup and dismantling makes them a cost-effective solution for many businesses.

Conclusion

The effectiveness of inflatable paint booths in managing overspray and contamination lies in their advanced filtration systems, thoughtful design, and the controlled environment they provide. These features not only ensure a high-quality finish for painting projects but also contribute to workplace safety and environmental protection. As the demand for efficient and flexible painting solutions grows, inflatable paint booths continue to be a preferred choice for many industries.