Inflatable paint booths have emerged as a convenient and versatile solution in the world of spray painting and automotive detailing. Their unique design and operational features offer an innovative approach to tackling painting projects. This article delves into how inflatable paint booths work, highlighting their design, operation, and the advantages they bring to various painting tasks.

Design and Structure

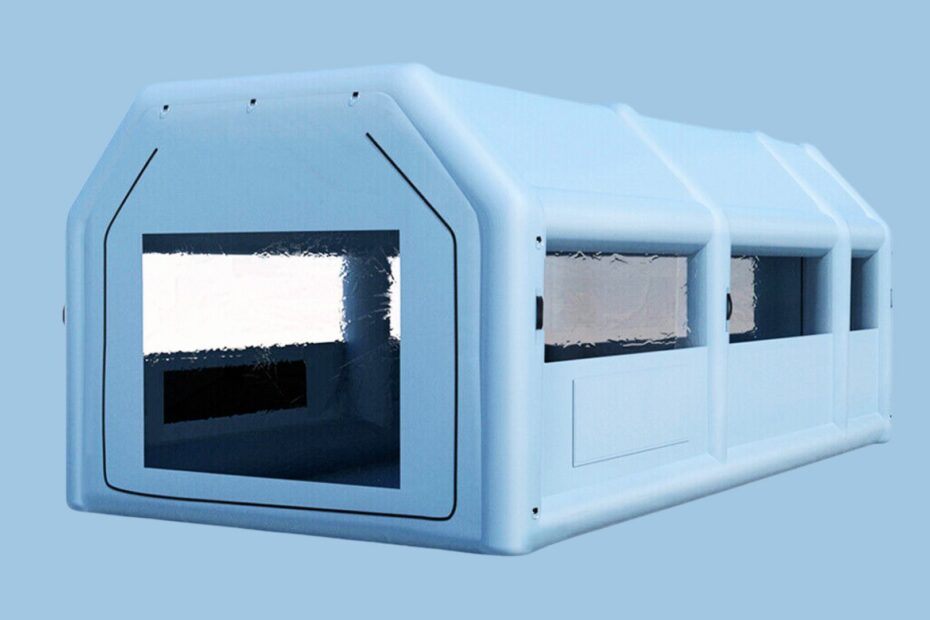

An inflatable paint booth is essentially a temporary structure made from durable, air-tight materials like PVC and nylon. These materials are chosen for their ability to withstand the rigors of painting environments while being lightweight and flexible.

- Inflatable Framework: The booth inflates to form a self-contained space, with inflatable beams providing structural support. This framework is designed to be robust enough to maintain its shape and withstand external elements like wind.

- Ventilation System: A key feature is the ventilation system, usually comprising air filters and exhaust fans. This system ensures that paint fumes are adequately removed from the booth, maintaining a safe environment for the operator and complying with health and safety regulations.

- Transparent Sections: Many booths include transparent sections or windows made from clear plastic. These allow natural light to enter the booth, improving visibility and accuracy in painting.

- Entrances and Exits: Doors or zippered entrances are incorporated into the design for easy access. Some larger models may include separate entrances for personnel and vehicles or equipment.

Operational Mechanism

- Setup: The booth is laid out flat on a clean, level surface and anchored securely. An electric blower is used to inflate the structure, which takes just a few minutes.

- Ventilation Activation: Once inflated, the ventilation system is activated. This typically involves starting the exhaust fans to create a flow of air that pushes out paint fumes and overspray, pulling in fresh air through the filters.

- Painting Process: Inside the inflated booth, the painting process is similar to that in a traditional paint booth. The contained environment prevents dust and debris from contaminating the paint job, while the ventilation system handles fumes and overspray.

- Deflation and Storage: After use, the booth is deflated by turning off the blower and allowing the air to escape. It can then be folded and stored, taking up significantly less space than a permanent structure.

Advantages of Inflatable Paint Booths

- Portability: Their lightweight and collapsible nature make them highly portable, ideal for on-site painting jobs or when workspace is limited.

- Cost-Effectiveness: Inflatable booths are generally more affordable than installing a permanent paint booth.

- Flexibility: They can be set up in various locations, both indoors and outdoors, offering flexibility that traditional booths can’t match.

- Environmental Control: Provides a controlled environment that minimizes contamination and improves the quality of the paint job.

Conclusion

Inflatable paint booths represent a significant advancement in painting technology, offering efficiency, flexibility, and cost-effectiveness. Their unique design and operational mechanism cater to a wide range of painting needs, from automotive work to industrial applications. By understanding how these innovative booths function, users can effectively harness their benefits for high-quality, efficient painting projects in a variety of settings.